Main site – English

Our company BETOMET Sp. z o.o. presents you with an innovative technology of magnetic formwork which has found its wide application in plants producing precast concrete, among others such as wall and ceiling elements, piles, columns, bolts, road plates and many others.

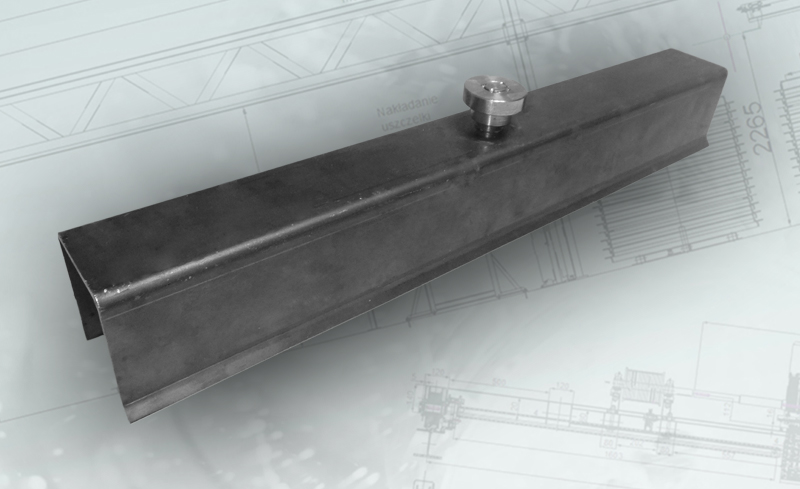

Shuttering magnets for the production of concrete elements. A wide range of production possibilities. The perfect solution for fast, trouble-free work.

Formwork systems for horizontal production of concrete products. Easy assembly and fast production.

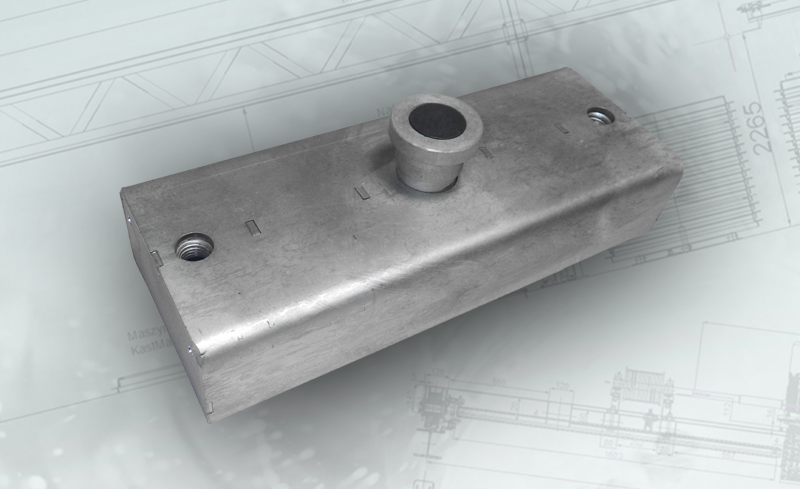

Magnets for mounting: threaded sleeves, magnetic holders, electrical boxes and others.

Magnets for mounting: threaded sleeves, magnetic holders, electrical boxes and others.

Magnetic triangles for forming chamfers, profiles of various shapes are made of steel or plastic with an integrated magnet.

The magnetic formwork technology is very easy to use, and at the same time greatly simplifies the production process. In combination with the magnets, magnetic profiles and triangular strips we offer, they allow for the appropriate shape of the prefabricated element.

Depending on the height of the prefabricated element, we use appropriate formwork handles or adapters with magnets intended for them. The formwork system must be fixed on the vibrating table. After the concrete has set, the formwork system must be removed from the mold by removing the hardware.

We offer several magnetic formwork systems, a wide selection of magnets, magnetic profiles and triangular slats.

If you have any questions, please do not hesitate to contact us!